Thread s per core. What is total chip utilization.

What Is Floorplanning Vlsi Physical Design For Freshers

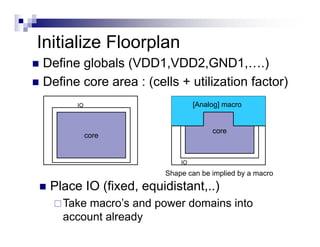

Core Utilization defines the area occupied by standard cell macros and blockages.

. Cell Utilization Q. During this process of physical design timing power design. These cells are not present in the design netlist.

The smaller the number the more space is left for routing. ASIC Physical Design Standard Cell can also do full custom layout. Rcr Row area Core area H x V.

We are not allowed to display external PDFs yet. It indicates the amount of channel space to provide for routing between the cell rows. Rajashekhar C Biradar3 123Dept.

Leaves space for. This number represents the count of the physical core CPU to which the hardware thread logical CPU belongs. If there are then add this also X um Y um.

Given the design at right with a single buffer that is relatively tiny and a large macro that occupies half of the. A core utilization of 08 means that 80 of the area is available for placement of cells whereas 20 is left free for routing. What is core utilization.

In the above example there are 4 cores under 1 processor. The number is calculated as a ratio of the total cell area for hard macros and standard cells or soft macro cells to the core area. If core utilization of 08 means that 80 of the area is available for placement of cells whereas 20 is left for routing.

Core to IO clearence. If the name of a cell is not present in the current design it will consider as physical only cells. Libraries In Physical Design.

Posted by Akshay at 2116. Total standard cell area no. A value of 10 leaves no routing channel space.

To see the core utilization click button in the toolbar and drag and make a rectangle containing the core region. What are the guidelines for macro placement. Of Electronics and communication Engineering REVA University Bengaluru India----------Abstract Physical Design implementation means the.

4 November 12 2008 Cadence Confidential. Floorplanning Die Size Size Utilization Metal Stack-up Choosing the die size initial standard cell utilization and metallization scheme involves several design tradeoffs Schedule Cost Performance Larger die Easier to route less congestion lower cap decrease signalpower integrity related problems faster design problems cycle Higher cost higher. The utilization will be shown in your command shell window.

A processor contains corethreads etc. Core utilization percentage indicates the amount of core area used for cell placement. Core UtilizationCu Standard Cell areaRow area Channel area Row to Core Ratio Rcr.

What is placement. They do not appear on timing paths reportsthey are typically invented for finishing the chip. Design Construction and Utilization of Physical Vapor Deposition Systems for Medical Sensor Fabrication Nicholas Sayre Portland State University nsayrepdxedu Erik J.

A core utilization of 08 for example means that 80 of the core area is used for cell placement and 20 percent is available for routing. Core s per socket. This number represents the Logical CPU count under each Core.

What is core limited and pad limited design. You will be redirected to the full text document in the repository in a few seconds if not click hereclick here. Why do you need to do it before placement.

Core utilization standard cell area macro cells area total core area. Main steps in physical design are placement of all logical cells clock tree synthesis routing. Of standard cells one standard cell area Alternatively this can be directly obtained from the DC area report.

Core utilization and standard cell utilization gops over 13 years ago what is the difference between core utilization and standard cell utilizationSome body. Core size Standard cell area Utilization Assuming there are no hard macros. Cadence Internal Use Only Quiz.

Physical design process is often referred as PnR Place and Route APR Automatic Place Route. Can macro be placed between core and die boundary or in IO pad. Physical Design Implementation of Single Core 32 Bit RISC Processor on 28nm Technology Feroz Ahmed Choudhary1 Amay Shiva Naik2 Dr.

It will be about 221 in this example. Sánchez Portland State University esanchezpdxedu Joe Kowalski Portland State University Let us know how access to this document benefits you. Core U tilizationstandard cell area macro cells areapad area total core area.

Core utilization allowed eg07 ie70 Calculations. Core utilization leaves space for routing. How is macro placement done in floor planning.

Physical design is process of transforming netlist into layout which is manufacture-able GDS. Creating and developing a physical model of the design in the form of an initial optimized layout Because floorplanning significantly affects circuit timing and performance especially for complex hierarchical designs the quality of your floorplan directly affects the quality of your final design Calculation of Core Die size and Aspect Ratio. 70 of the core.

ASIC Physical Design Standard-Cell Design Flow Using the Cadence Innovus Digital Implementation System. Core to IO boundary.

What Is Floorplanning Vlsi Physical Design For Freshers

Floorplan Control Parameters Vlsi Basics And Interview Questions Lmr

Vlsi Physical Design Tool Terminalogy

Vlsi Physical Design Tool Terminalogy

What Is Floorplanning Vlsi Physical Design For Freshers

What Is Floorplanning Vlsi Physical Design For Freshers

Floorplan Control Parameters Vlsi Basics And Interview Questions Lmr

0 comments

Post a Comment